Mapping Energy Use and Implementing Energy Efficiency Measures in a Food Processing Facility

Objective/short description

This thesis aims to map energy use across different processes in a food processing facility and identify where energy is being used and wasted. By analyzing current consumption patterns and evaluating practical energy efficiency measures, the project explores how Orkla Foods Sverige facilities can reduce energy costs, improve sustainability, and benchmark its performance enabling comparison with industry peers.

Background

Food systems are responsible for approximately 30% of global greenhouse gas (GHG) emissions, posing a significant challenge in meeting the dual demands of a growing global population and increasingly urgent sustainability goals. A major contributor to these emissions is the energy-intensive nature of food-related activities, particularly within the food processing sector.

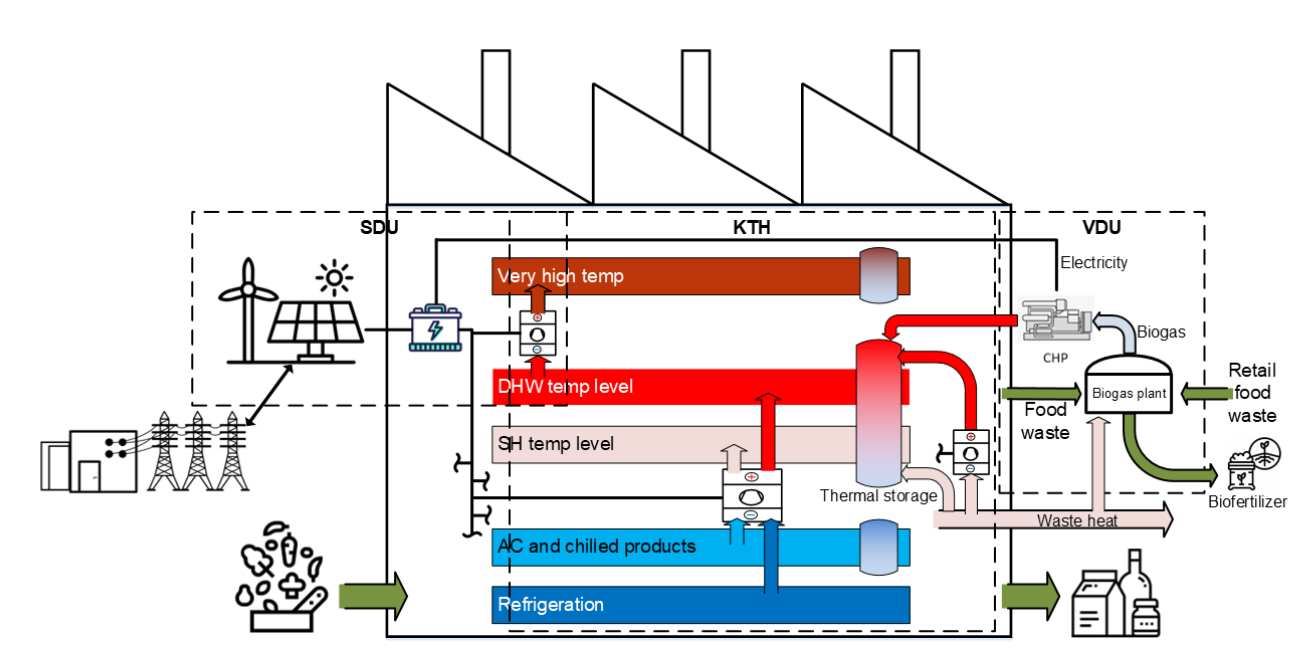

Research indicates that global food systems are becoming more energy demanding, with the food processing industry accounting for around 12% of total industrial energy consumption in Europe. This sector’s energy usage is not only high in quantity but also complex in nature. Food manufacturing processes typically require simultaneous heating (at varying temperature levels up to 200°C), cooling, and refrigeration. These operations generate multiple hot and cold streams at different temperature levels, which present opportunities for energy integration through advanced heat recovery techniques, see simplified process in the provided figure.

Modern heat pump technologies offer promising solutions for reusing waste heat within food processing facilities. By reintegrating waste heat back into the process, the overall energy demand can be reduced, leading to improved energy efficiency and lower operational costs. However, before such systems can be implemented effectively, a detailed understanding of current energy flows is essential. Mapping energy use across a facility allows for the identification of waste heat streams, their capacities, and the temperature levels at which heat is being lost. This knowledge is critical for determining the feasibility and design of high-temperature heat pump (HTHP) systems.

HTHPs represent an emerging technology with the potential to significantly reduce fossil fuel dependency in industrial heating. While current commercial heat pumps are largely limited to supply temperatures below 100°C, many industrial processes, especially in food processing, require temperatures well above this threshold. At present, HTHPs capable of delivering heat above 100°C are mostly in the prototype or laboratory development stage. Expanding the operational range of HTHPs to supply heat up to 200°C could potentially meet 37% of the process heat recovery needs in Europe’s industrial sector.

Therefore, this project aims to address a key challenge in the food processing industry: the development of sustainable and cost-effective energy systems. Specifically, it focuses on mapping energy use within food processing facilities and identifying opportunities for waste heat recovery, with an emphasis on the potential application of high-temperature heat pumps.

This project is a task within the project PLENTY – a Centre for a Symbiotic and Circular Food Provisioning and in cooperation with Orkla Foods Sverige .

Task description

-

Review and summarize existing studies on energy use in the food processing industry.

-

Map current energy consumption and identify waste heat streams within the selected food processing facility.

-

Survey, select, and evaluate applicable energy efficiency technologies for waste heat recovery.

-

Estimate potential energy savings, cost reductions, environmental benefits, and payback periods for the selected measures.

-

Propose benchmarking metrics to assess and monitor energy efficiency at both the process and facility levels, enabling comparison with industry peers.

Learning outcomes

By the end of this thesis project, the student will be able to:

-

Analyze energy consumption patterns in industrial food processing, including process-level energy demand and temperature requirements.

-

Identify and quantify waste heat generated within a processing facility, including understanding their recovery potential.

-

Select and assess high temperature heat pumping solutions applicable to food processing facilities.

-

Perform technical, environmental, and economic assessments, including energy savings, CO₂ reduction, investment cost, and payback time calculations.

-

Communicate complex technical findings effectively through structured reports and presentations tailored to both technical and non-technical audiences.

Duration

Starting in January 2026