New opportunities for R32

written by Pavel Makhnatch (under supervision of Rahmatollah Khodabandeh and Björn Palm)

R32 is a refrigerant that has been known for years. As a component of R410A it is used in many residential refrigeration systems, but as a pure refrigerant it has not been used until recently. As many refrigerants, R32 balances between good and bad properties: It has favorable thermodynamic properties that lead to energy efficient units with smaller size; it is also flammable and forms poisonous hydrogen fluoride during combustion. In this article we will discuss R32 and its place in the future list of refrigerants for the future.

R32

R32 (Difluoromethane, HFC32, Methylene difluoride) is a single component refrigerant with critical pressure of 53.8 bar and -51.65 °C and 78.4 °C boiling point and critical temperatures respectively. As a substance, it has been studied for many decades, with the extensive research interest seen during the beginning of the 90ties, when the replacements for ozone depleting refrigerants have been searched for.

In mixture with R125, R32 has been used to replace the ozone depleting R22 in small air conditioning systems and heat pumps. Considering generally better properties of R32, compared to R125, the later led to degradation of properties of the mixture while it has been used as a fire suspension agent in order to mitigate R32 flammability. The 50/50% mixture of R32 with R125 is known as R410A and become a popular refrigerant used nowadays.

R32 in the perspective of F-gas regulation

The recent F-gas regulation requires steep reduction in high GWP refrigerant usage. R410A is a strong greenhouse gas with GWP of 2088. A number of lower GWP R410A replacements has been proposed by different manufacturers, however all of them are flammable (Table 1).

Table 1 - List of low GWP refrigerant candidates [1]

| Refrigerant |

Refrigerant |

(Mass%) |

Classification/expected classification |

GWP100 (estimated) |

| ARM-70a |

R-32/R-134a/R-1234yf |

(50/10/40) |

A2L |

482 |

| D2Y60 |

R-32/R-1234yf |

(40/60) |

A2L |

272 |

| DR-5 |

R-32/R-1234yf |

(72.5/27.5) |

A2L |

490 |

| HPR1D |

R-32/R-744/R-1234ze(E) |

(60/6/34) |

A2L |

407 |

| L41a |

R-32/R-1234yf/R-1234ze(E) |

(73/15/12) |

A2L |

494 |

| L41b |

R-32/R-1234ze(E) |

(73/27) |

A2L |

494 |

| R-32/R-134a |

R-32/R-134a |

(95/5) |

A2L |

713 |

| R-32/R-152a |

R-32/R-152a |

(95/5) |

A2L |

647 |

| R32 |

R32 |

100 |

A2L |

675 |

While many of the proposed refrigerants have potential to replace R410A, R32 is the one the most studied. It has GWP value of 675, that is 3 times lower than that of R410A. Its thermodynamic and transport properties are well known and its vapor pressures are close to that of R410A.

The main limiting factor that restricts widespread use of R32 is that it is flammability. However, considering the requirements of F-Gas Regulation and absence of non flammable R410A replacement flammability is something engineers will have to deal with in the future refrigeration systems.

Flammability concerns of R32

Under EU regulations, R32 is classified as extremely flammable gas (category 1 flammable) as have greater than 12% flammability range by volume (14 % - 33 % by volume) [2] [3]. Contrary to this definition, R32 belongs to mildly flammable A2L class by ASHRAE Standard 34 as has low burning velocity. Thus, the confusion around the R32 arose. Still, by any considerations, R32 is flammable, and as many other HFC refrigerants forms dangerous hydrogen fluoride when ignited. However, the flammability is unlikely to occur as big quantity of refrigerant is required to be present in the atmosphere in order to sustain combustion.

Current European standard EN378 on safety and environmental requirements of refrigeration systems and heat pumps does not recognize A2L ASHRAE classification and therefore classifies it under the flammable A2 category. The standard recognizes 3 room occupancy classes (general, supervised and occupancy with authorized access only) and 3 locations of refrigerant systems (e.g. entirely in an occupied place; in an unoccupied machine room) for either direct or indirect refrigeration system. For instance, for A/C systems and heat pumps for human comfort the maximum allowed charge will be generally calculated based on the following formula:

mmax=2.5 x LFL5/4 x h0 x A1/2

where

mmax- is the allowable maximum charge in a room in kg;

LFL - is the Lower Flammable Limit (LFL) in kg/m3 (LFL for R32 = 0.306 kg/m3);

h0 - is the installation height of the appliance in m;

A - is the room area in m2;

Thus, for instance, for a ceiling mounted indoor unit using R32 placed in the room with dimensions 7x 4 m the maximum allowable charge equals 2.5 x 0.3065/4 x 2.2 x (7x4)1/2 = 6.62 kg, which is quite a large charge that is due to the high LFL value for R32.

The requirements are different for other applications and some ranges of refrigerant charge. We therefore refer reader to the EN378 standard itself for the complete list of requirements.

Last but not least, flammability of R32 puts requirements on the technicians that should be skilled enough to handle flammable refrigerants.

R32 properties performance

Performance data for R32 is widely available. Generally it is characterized with “superior” properties and therefore seen as a component of almost every lower GWP replacement blend [1] [4] [5].

Some thermodynamic data is listed in the Table 2.

Table 2 – Selected properties of R410A and R32 in typical condensing and evaporative conditions [5]

| Parameter |

Unit |

R410A |

R32 |

||

| Temperature |

°C |

44 |

10 |

44 |

10 |

| Saturated vapour pressure |

kPa |

2653 |

1081 |

2729 |

1107 |

| Latent heat |

kJ kg-1 |

151.7 |

209.9 |

226.7 |

298.9 |

| Liquid specific heat |

kJ kg-1 K-1 |

1.89 |

1.57 |

2.25 |

1.80 |

| Vapour specific heat |

kJ kg-1 K-1 |

1.94 |

1.23 |

2.07 |

1.34 |

| Liquid thermal conductivity |

mW m-1 K-1 |

75.1 |

98.1 |

105.1 |

136.4 |

| Vapour thermal conductivity |

mW m-1 K-1 |

18.7 |

13.6 |

21.4 |

15.3 |

Compared to R410A, R32 have generally higher values of latent heat, specific heat of liquid and vapor, and higher thermal conductivity, that generally can allow building more efficient and compacting refrigeration system, compared to R410A.

Considering favorable thermodynamic and transport properties, good energy performance of the R32 system, reduced GWP values and taking in account flammability concerns, a number of manufacturers have introduced R32 equipment.

R32 based equipment is in use.

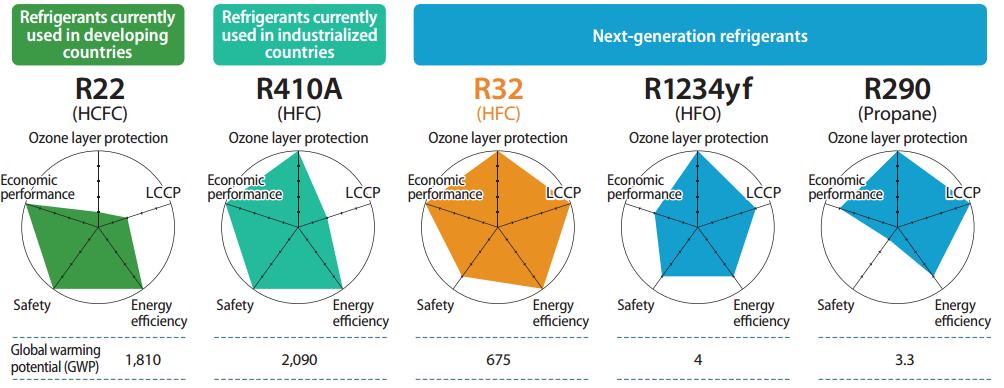

Daikin was the first company to release R32 based residential air conditioner in November 2012, which is sold in 30 countries by now [6]. It has been selected by Daikin as its overall characteristics are better than that of the alternative refrigerants for residential and commercial air conditioners (Figure 1) [REF]. In addition to the air conditioning equipment, Daiking is rumored to launch R32 heat pump under the name “Neo Cute” which is seen to compete with EcoCute series of CO2 based heat pumps popular in Japan [7].

Other manufacturers, including Mitsubishi, Panasonic and others have announced R32 air conditioners and components to them, however they are still under development or only available on selected markets.

R32 can be seen as a R410A alternative refrigerant as soon as flammability is taken into account. Any other blends with HFO have not been studied well enough and for the moment do not provide significant benefits, taking into account their GWP values and higher costs. With some time and additional research, they may find their niche applications where they can provide additional reductions of GWP.

The main drawback of R32 is its flammability. While it is definitely a limiting factor that requires additional attention at different stages of refrigeration equipment design, installation, maintenance and use; it can be addressed by proper design and strict procedures.

Följ gärna våra publikationer och få vårt digitala nyhetsbrev. Anmäl dig genom att följa länken bit.ly/kth_ett.

Works Cited

| [1] |

X. Wang and K. Amrane, "AHRI low Global Warming Potential alternative refrigerants evaluation program (Low-GWP AREP) - summary of phase I testing results," in 15th International Refrigeration and Air Conditioning Conference, Purdue, 2014. |

| [2] |

European Commission, "Regulation (EC) No 1272/2008 on classification, labeling and packaging of substances and mixtures," Official Journal of the European Union, 2008. |

| [3] |

BOC, "Safety data sheet. Difluoromethane (R 32)," 11 05 2011. [Online]. Available: bit.ly/R32_safety. |

| [4] |

ACR jounal, "Introduction to R32," 12 March 2015. [Online]. Available: bit.ly/CPDR32. |

| [5] |

X. Xu and Y. Hwang, "Performance comparison of R410A and R32 in vapor injection cycles," International Journal of Refrigeration, vol. 36, no. 3, p. 892–903, 2013. |

| [6] |

Daikin group, "Taking the next-generation refrigerant R32 around the world," 2014. [Online]. Available: bit.ly/daikin_R32. |

| [7] |

Cooling Post, "Daikin to introduce R32 heat pump," 26 Jan 2015. [Online]. Available: bit.ly/R32_heatpump. |