Stability and compatibility of HFOs

written by Pavel Makhnatch (under supervision of Rahmatollah Khodabandeh and Björn Palm)

Rapid adoption of HFOs as R-134a replacement in automotive air condition systems is rising up the thermal stability and material compatibility issues.

New legislations which control use of the number of substances in refrigeration systems force refrigeration industry to adopt new refrigerants. Rapid adoption of HFOs as R-134a replacement in automotive air condition systems is rising up the thermal stability and material compatibility issues. Both theoretical studies and practical observations show HFCs and HCFCs being stable and compatible with materials used in the systems. However, for HFOs not enough information is available as there were no long term running systems to observe. In order to estimate the stability and compatibility, a specially designed test can be held. The procedure of the test is described under the ANSI/ASHRAE Standard 97-2007 “Sealed Glass Tube Method to Test the Chemical Stability of Materials for Use within Refrigerant Systems” and utilizes sealed glass tubes for the evaluation of materials for use in refrigerant systems. It implies aging the sealed glass tube contents (refrigerant, lubricant, and metal coupons) under increased temperature of 175 oC for 14 days.

Several tests on HFOs stability and compatibility were performed by date with AHRTI “Material compatibility and lubricants research” on thermal and chemical stability of low GWP refrigerants with lubricants as most recent and profound. In this research AHRTI has tested three HFO refrigerants including HFO-1234yf, HFO-1234ze and HFO-1234yf/R-32 (50/50 weight %). The refrigerants were tested with three lubricants (mixed acid POE, branched acid POE and PVE oil) and three contaminants (air, water, air and water) and the results were compared with control samples. Similarly to the previously known results, no degradation of either the HFO-1234yf refrigerant-oil blend or metal coupons was observed as a result of the test. However, the increased scope of the test by AHRTI, which included testing the stability in presence of water or/and air, has revealed that the decomposition of refrigerant take place. The decomposition is taking place both for the refrigerant and the lubricant and is high when the refrigerant/oil mixture is aged in the presence of air and moisture.

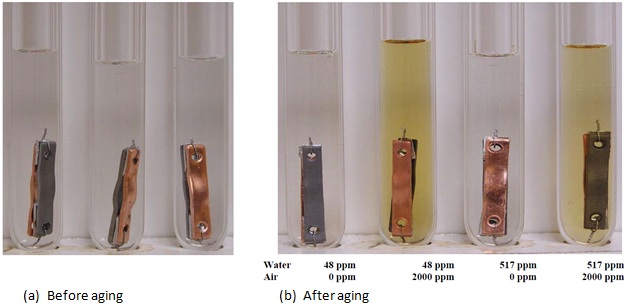

Figure 1 present the photographs of sealed tubes containing HFO-1234yf/ISO 32 branched acid before and after aging. As we can see from the pictures, the color of liquid is after aging is darker. With the aid of Ion and Gas Chromatography, the reason for the color change can be determined.

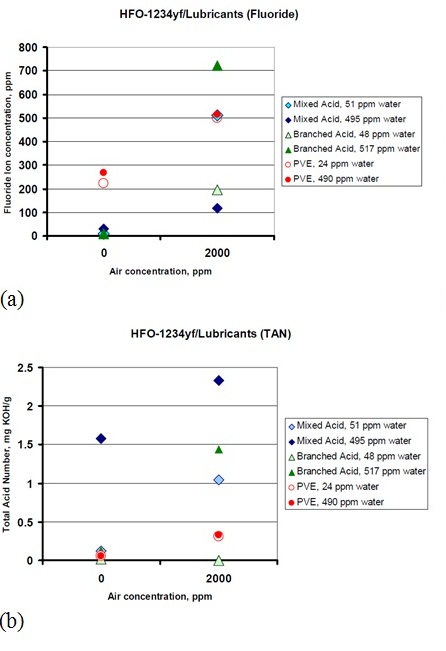

As we can see from the charts on Figure 2, the highest fluoride ion concentration (which is an indicator of refrigerant decomposition) was recorded when the refrigerant was aged with ISO 32 Branched Acid in the presence of air and water. Increases in TAN, indicated on the Figure 2b, in turn, indicate lubricant decomposition, and are maximal for ISO32 Mixed Acid oil aged with refrigerant in the presence of air and water.

Concluding the report, AHRTI stated that with HFO-1234yf and HFO-1234yf/R-32 the presence of air contributed to higher refrigerant decomposition at low as well as at high moisture levels, where as HFO-1234ze was more stable than these refrigerants and R-134a and R-410A, in contrast, showed no refrigerant decomposition. The report highlighted the compatibility problems which were not shown before. Similarly, the compatibility tests of HFO-1234yf and HFO-1234ze with plastics and elastomers have shown high stability in presence of PAG or POE libricants with similar behaviour to R-134a. Hovewer, more test results with different contaminating substances desirable in order to draw certain conclusions.