In short about R1234ze

written by Pavel Makhnatch (under supervision of Rahmatollah Khodabandeh and Björn Palm)

According to the recent announcement from Honeywell, the company has started full-scale production of R1234ze(E) – low global warming potential refrigerant with GWP of less 1 [1] . We therefore have a brief look at its properties and application.

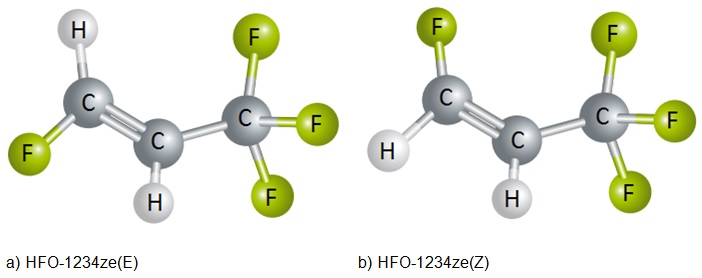

R1234ze isomers

Refrigerant R1234zeE (trans-1,3,3,3-Tetrafluoroprop-1-ene, CF3CH=CHF ) belongs to the family of HFO fluids that contain a carbon-carbon double bond and characterized by very low GWP of less than one [2]. It should be noted that the molecule of R1234ze has 2 isomers, R1234ze(Z) and R1234ze(E) (see Figure 1), with rather different properties. R-1234ze(Z) has a high boiling point (9.8°C) associated with a higher critical temperature (153.7°C) and a volumetric capacity roughly 50% lower than R-1234ze(E). Therefore R-1234ze(Z) could be primarily utilized in specific applications like high temp heat pumps, whereas R-1234ze(E) will show operating conditions and applied costs much more in line with R-134a according to system and compressor sizes.

In the previous articles we have already discussed the R1234ze(Z) isomer [3], and therefore the focus of this article is entirely given to R1234ze(E).

Physical properties

Similarly to R134a, R1234ze(E) is a medium pressure refrigerant with a slightly higher critical and boiling temperatures and lower critical pressure. Some of the properties of R1234ze in comparison to R134a are listed in the Table 1.

Table 1 - Physical properties of R1234ze(E) [2] [4]

| R1234ze(E) |

R134a |

|

| Molecular weight, kg/mol |

114 |

102 |

| Boiling point at 101.3 kPa, °C |

-18,95 |

-26,06 |

| Critical temperature, °C |

109,4 |

101,1 |

| Critical pressure, bar |

36,4 |

40,6 |

| Latent heat of vaporization at 30 °C, kJ/kg |

162,9 |

173,1 |

| Critical density, kg/m3 |

489 |

515,3 |

R1234ze(E) is characterized by lower vapour pressures, compared to R134a (Figure 2). This is one of the reasons it is not suitable as R134a drop-in replacement.

Refrigerant is compatible with most common materials. However, the manufacturer suggests to consult equipment producer of conduct additional independent testing prior using the refrigerant in new systems as R1234ze(E) have shown to be unsuitable with some materials (e.g. acrylic substances) and suitable under certain conditions with a number of other substances (e.g. neoprene, polypropylene and etc.) [2]

Polyol ester (POE) oil is recommended for using R1234ze(E). However, due to the higher than most of traditional HFCs miscibility of R1234ze with oils, it is suggested to use lubricants, recommended by compressor manufacturers in order to avoid potential problems with lowered viscosity of the refrigerant-lubricant mixture [2].

Toxicity and flammability

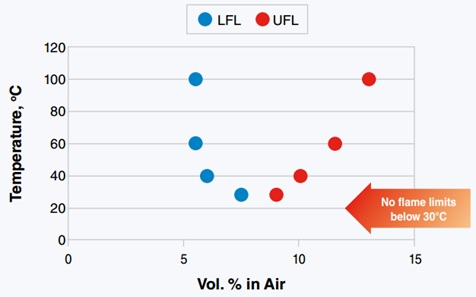

ASHRAE classifies R1234ze(E) as mildly flammable refrigerant. However, at temperatures under 30 it does not form flammable mixtures with air and therefore could be considered as non flammable for handling and storage (Figure 3).

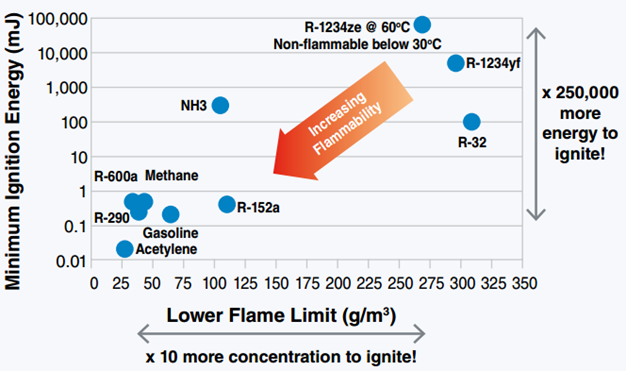

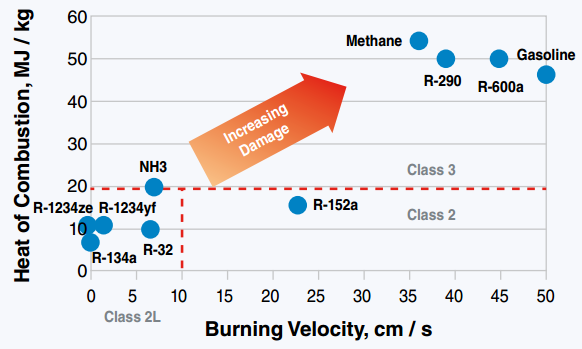

At the temperatures above 30, its flammability characteristics are lower than other mildly flammable refrigerants as R1234yf and R32 (Figure 3 and 4). Compared to hydrocarbons, R1234ze(E) needs 10 times more concentration and 250,000 times more energy to become flammable (Figure 4). In case of a flame occurring, the effect of this flame would be extremely mild, as its very low heat of combustion (5 times less than propane) associated to a low burning velocity wouldn’t be enough to propagate a fire (Figure 5).

Toxicity levels of R1234ze(E) are favorable and comparable to that of R134a.

Applications

HFO-1234zeE is the medium pressure refrigerant that is alternative to traditional refrigerants in air-cooled and water-cooled chillers for supermarkets and commercial buildings. It could be also used in other medium-temperature applications like heat pumps, refrigerators, vending machines, beverage dispensers, air dryers and CO2 cascade systems in commercial refrigeration [2].

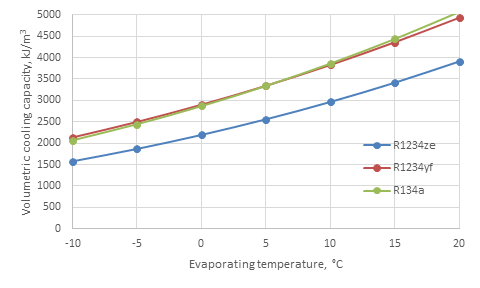

Several studies evaluate the applicability of R1234ze in various application [5] [6] [7] [8]. Generally, the refrigerant has comparable COP, but lower capacity than R134a (theoretical volumetric cooling capacities presented on Figure 6). The later could be a problem when using it as a drop-in replacement, but can be addressed when designing new equipment or adjusting existing one to reflect lowered capacity of R1234ze(E). Since the installation of first R1234ze(E) chiller more than 2 years ago, a number of manufacturers have introduced chillers running on this low GWP refrigerant [9].

Another important application of R1234ze(E) is being a component of many refrigerant blends. For instance, the blends with R134a are considered as lower GWP R134a replacements, and compositions with R32 has been studied in comparison to R410A refrigerant. Small quantity of R1234ze(E) is used in R448A refrigerant, that is a replacement to R404A.

Conclusions

As pure substance R1234ze(E) is seen as the R134a replacement. However, its volumetric refrigerating capacity is below that of R134a and R1234yf. It\s boiling point is also higher than that of R134a. It is therefore R1234ze(E) can not be considered as a drop-in replacement of R134a, but instead should be considered in new designs of medium temperature equipment.

Up to day there was no big incentives to use R1234ze(E). With the adoption of new F-gas regulation that aims to significantly reduce use of HFC, and with introduction of standards that will facilitate use of mildly flammable refrigerants, we will see the increase of interest to this refrigerant.

Bibliography

| [1] |

Honeywell, "Honeywell Starts Full-Scale Production Of Low-Global-Warming Propellant, Insulating Agent, And Refrigerant," 5 1 2015. [Online]. Available: bit.ly/honeywell_ze. [Accessed 2015]. |

| [2] |

Honeywell, "Solstice ze refrigerant (HFO-1234ze). The Environmental Alternative to traditional refrigerants.," 2014. |

| [3] |

P. Makhnatch, R. Khodabandeh and B. Palm, "Köldmedier med låg GWP för högtemperaturvärmepumpar," KYLA+ Värmepumpar, Jul 2014. |

| [4] |

DuPont, "DuPomt Suva. Thermodynamic properties of HFC-134a," 2004. |

| [5] |

K. Schultz and S. Kujak, "System drop-in tests of R134a alternative refrigerants (ARM-42a, N-13a, N-13b, R-1234ze(E), and Opteon XP10) in a 230-RT water-cooled water chiller," AHRI, 2013. |

| [6] |

D. Shapiro, "System drop-in tests of R-134a, R-1234yf, Opteon XP10, R-1234ze(E), and N13a in a commercial bottle cooler/freezer," AHRI, 2013. |

| [7] |

"System drop-in test of R134a alternative fluids R-1234ze(E) and D4Y in a 200 RT air-cooled screw chiller," AHRI, 2013. |

| [8] |

S. Fukuda, C. Kondou, N. Takata and S. Koyama, "Low GWP refrigerants R1234ze(E) and R1234ze(Z) for high temperature heat pumps," International Journal of Refrigeration, vol. 40, pp. 161-173, 2014. |

| [9] |

Cooling post, "Cofely introduces R1234ze chiller," 1 Aug 2914. [Online]. Available: bit.ly/r1234ze_chiller. |