Key news in low GWP refrigerants developments

written by Pavel Makhnatch (under supervision of Rahmatollah Khodabandeh and Björn Palm)

Recently held IIR International Congresses of Refrigeration has brought together large numbers of refrigeration stakeholders from all parts of the world. Among many presentations held during the congress, a great number were devoted to new refrigerants and the challenges we face in order to transit towards more environmentally friendly refrigerants. This article will highlight the key development trends in new low GWP refrigerants, spotted during the ICR2015 congress.

More new refrigerants introduced

Activities in refrigerant development are far from being complete. Systems that rely on natural refrigerants and cover all possible needs are still under development. During the same time, the pressure on HFC increases globally. In addition to European regulations, US recently has come out with the rule that makes some conventional refrigerants to be not allowed in certain applications. As for instance, R134a will be not allowed in new cars’ mobile air conditions in US, as well as R404A is not allowed in new commercial refrigeration systems already since 2017 [1]. It is therefore need for new low GWP refrigerants is ever high nowadays.

During the congress, the new results have been presented regarding the theoretical screening of potential low GWP substances. We have discussed the first phase of this work is previously and shown the way researches screened over 100 million chemical compounds to gradually reduce that number to 1234 low GWP refrigerants that may be considered for further analysis [2]. This list is now further narrowed down to 21 fluids, that represent the most promising medium- and high-pressure low-GWP candidates [3]. These fluids were further analyzed to predict their cycle performance [4] and the results were listed as well. In short, researchers conclude that there is a finite number of possible combinations allowed by the rules of chemistry and it appears that “we have hit the limits of what chemistry allows”, and it will be particularly hard to find a nonflammable replacement to high capacity fluids like R410A [3].

These suggested new molecules will definitely be in focus in upcoming refrigerant developments. However, refrigeration industry, which at the moment faces a number of regulations, requires low GWP refrigerants that are well studied and can be available for use in nearest future. Big chemical companies are set to fulfill such needs. For instance, Chemours (formerly Dupont) has presented several new refrigerants, including DR-55 and DR-5A (R-454B, pending), that are 2L flammable replacements to R410A with GWP values of 678 and 467 respectively. Those refrigerants have been known before, but now it seems that Chemours has decided to actively market this refrigerants and we likely will hear more about them in coming future. The main competitor to these refrigerants is R32, but Chemours position their refrigerant as having similar to R410A pressures and cycle performance and therefore state that “they are being considered by some users as “drop-in” replacements” [5].

Many studies about HFO, their properties and potential use were shown during the congress as well. In addition to R1234yf and R1234ze(E), that are studied quite well by this time, it is clearly seen increased interest to R1234ze(Z), which is the potential fluid suitable for high temperature heat pump applications. Another frequently mentioned refrigerant is R1233zd(E), which is sold by Honeywell primarily as a blowing agent [6] and proposed as a refrigerant for chiller applications, as well as R1225ye(Z). Particularly interesting was molecule R1123, developed by Asahi Glass Co. and suggested as potential R-32 replacement with significantly lower GWP of 0.3. However, the major drawback of this molecule is its high instability, so that it should be combined with other substances (e.g. R32) in order to get used in practical applications.

Advancements in CO2 refrigeration has been shown as well. The main current focus of current developments is to optimize the cycle to provide efficient operation under the warmer climate conditions. In colder climates CO2 systems already more efficient, and therefore can be considered as replacement to conventional systems using R404A. In addition, it is worth to mention that, HCFC refrigerants are still used in many countries. It is therefore, quite a number of speakers have presented their work on R22 replacement in a number of applications.

Focus on flammability

As many new low GWP refrigerants are flammable, there are risks associated with their use in refrigeration systems in case of the refrigerant ignition. While international standards subdivide flammability in few classes, every substance is different and possess different flammability properties. Therefore, it is important to better understand the characteristic of flammable refrigerants in order to design safe system and account for the risks.

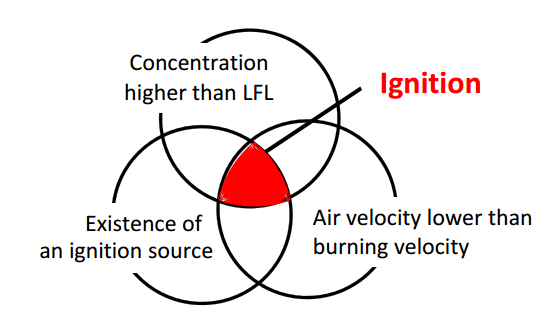

In test conditions, the tested flammable refrigerant is ignited by the spark or any other controlled method. In real life, however, the probability of ignition is a combination of other probabilities that should occur simultaneously: probability of refrigerant leakage, concentration in certain levels and existence of an ignition source (Fig 1). The effect of the resulting fire is also varying and depend on the burning velocity and heat of combustion.

During the congress several studies have been presented showing the flammability limits measuring, flame propagation and burning velocity measurement for existing and new flammable refrigerants. We have discussed these topics in our previous publications and therefore refer interested persons to them.

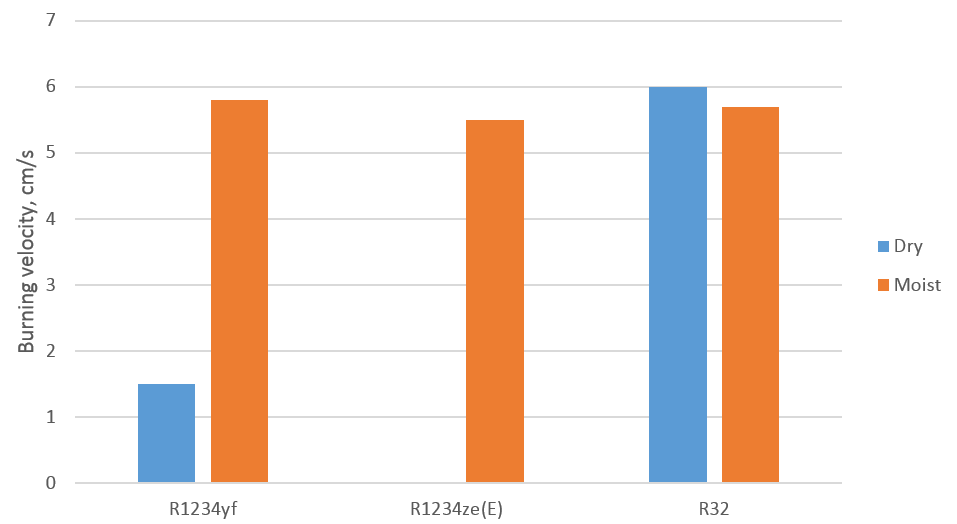

Particularly interesting was the study presenting humidity effects on flammability. In fact, the humidity can increase flammability of certain refrigerants, as shown in the example on Figure 2. While flammability of R32 decreased at humid conditions, the burning velocity of R1234yf was shown to be increased, and nonflammable at normal conditions R1234ze(E) became flammable with the presence of moisture. This is particularly important, considering that the climates with hot and humid climates are also big markets for air-conditioning equipment, in which nonflammable alternative to R410A is not found yet.

Another study highlighted the possible risks of flammable refrigerant used in split AC unit. The current design of AC and installation practices lead that the high concentration of leaked refrigerant can occur near the wall below an AC unit. It was also noted that the effects are more significant if leakage occurs when the AC unit is off. These knowledge, as well as other presented findings (like a concept of quenching distance, proposed index for safety estimation, effect of inhibitors and other) can help industry to develop standards that will properly address the flammability issues. We will continue discussion of this topic in our future articles.

Focus on environmental properties

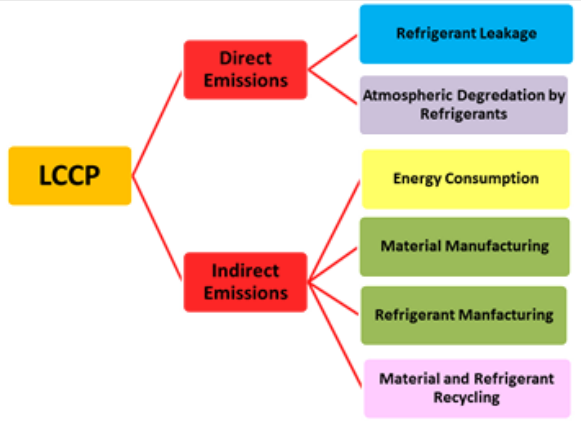

GWP is an easy to use index to compare substances based on their direct contribution to global warming. However, refrigeration systems use substantial amounts of energy during their operation, thus indirectly contributes to the global warming. Life Cycle Climate Potential (LCCP is a known tool, that provides holistic approach by accounting for both direct and indirect emissions, also including the emissions due to energy embedded in the material, used during transportation, during recycling and etc. (Figure 3).

During the congress, IIR held the workshop where presented the progress in development of LCCP methodology. The LCCP guideline has been proposed, that describes the methodology, as well as provides valuable information that is suggested to be used as an input to LCCP calculations (e.g. lifetimes and leakage rates of a number of various equipment).

However, the discussions that arose during the workshop suggest that proposed methodology is not complete yet. The main confusion comes from the unstandardized data sources for LCCP calculation, which in the end can make the transparent comparison of different LCCP values impossible. It was suggested to avoid oversimplifying the LCCP methodology. Instead, other metrics could be suggested that would allow simplified comparison of environmental effect of a system, similarly as gCO2/km index provides us simple metric of otherwise complex question of CO2 emissions of vehicle operation. For additional information and current status of the work we refer to the official website of LCCP evaluation working group [10].

While being far from the complete summary of the past congress, this article introduces recent trends in developments in the area of environmentally friendly refrigerants. With increasing demands for environmentally friendly efficient refrigeration equipment, the developments in the area are set to continue. We will continue to keep updating you with all the recent activities in this field. Samtidigt, följ gärna våra publikationer och få vårt digitala nyhetsbrev. Anmäl dig genom att följa länken bit.ly/kth_ett.

References

| [1] |

EPA, "Protection of stratospheric ozone: change of listing status for certain substitutes under the significant new alternatives policy program," 2015. |

| [2] |

"Sökandet efter nya köldmedier fortsätter!," KYLA+ Värmepumpar, June 2013. |

| [3] |

M. McLinden, S. Brown, A. Kazakov and P. Domanski, "Hitting the bounds of chemistry: limits and tradeoffs for low-GWP refrigerants," in The 24th IIR International Congress of Refrigeration, Yokohama, 2015. |

| [4] |

R. Brignoli and S. Brown, "Vapor compression cycle model capable of simulating well-described and not-so-well-described refrigerants," in The 24th IIR International Congress of Refrigeration, Yokohama, 2015. |

| [5] |

J. Hughes and T. Leck, "Novel reduced GWP refrigerant compositions for stationary air conditioning," in The 24th IIR International Congress of Refrigeration, Yokohama, 2015. |

| [6] |

Honeywell, "Honeywell Solstice 1233zd(E)," 2013. [Online]. Available: bit.ly/solstice1233zdE. |

| [7] |

JSRAE, "Risk assessment of mildly flammable refrigerants. 2014 Progress repor.," The Japan Society of Refrigerating and Air Conditioning Engineers , Tokyo, 2015. |

| [8] |

K. Takizawa, "Fundamental and practical flammability properties of 2L refrigerants," in The 24th IIR International Congress of Refrigeration, Yokohama, 2015. |

| [9] |

S. Troch, and Y. Hwang, "IIR working party life cycle climate performance guideline," 2015. |

| [10] |

IIR, "Working group on LCCP evaluation," 2015. [Online]. Available: bit.ly/IIR_LCCP_WG. |