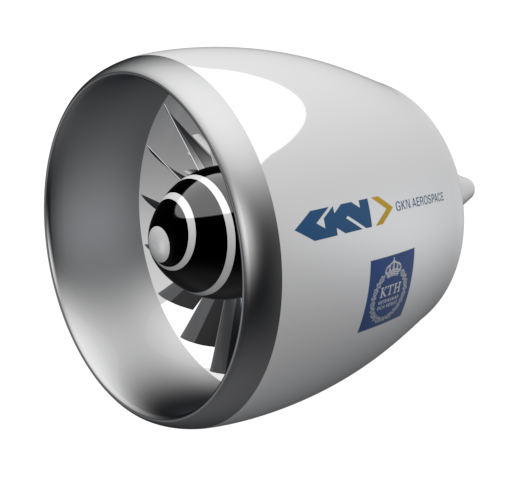

EleFanT – Electric Fan Thruster

Under the project, which spans over 1.5 years, GKN Aerospace and KTH will together develop fan technology for smaller regional aircraft. The project will study aerodynamic design, performance, noise and manufacturing technology for a ducted fan powered by electricity, either from batteries, hydrogen fuel cells or even more conventional hybrid propulsion solutions.

The proposed propulsion solution with a ducted fan instead of a conventional propeller offers significant advantages in three main areas: safety, noise level and engine installation. By rapidly demonstrating fan technology for electric aviation, the EleFanT project will accelerate the pace of electric aviation development and position the participants for international aero-engine and aircraft development projects.

Funded by

Swedish Energy Agency (through Fossilfritt Flyg 2045 program)

Time period:

1 July 2021 – 31 Dec 2022

Project partners

GKN AEROSPACE SWEDEN AB, Sweden

Aim and objectives

- Comparison of electric ducted fan and relevant propeller configuration

- Aerodynamic design of fan blades, OGVs and nacelle

- Performance analysis of electric fan thruster with respect to stability margins and efficiency

- Fan architecture will be presented in a 3D model where load carrying structures has been analyzed with respect to integration of electric motor

- Quantification of noise levels from the electric fan thruster for relevant flight envelope

- Choice of material for the key components motivated by safety, weight optimization and manufacturing aspects

- Pre-study of a new electric fan test rig and certification requirements