eLITHE – Electrification of ceramic industries high temperature heating equipment

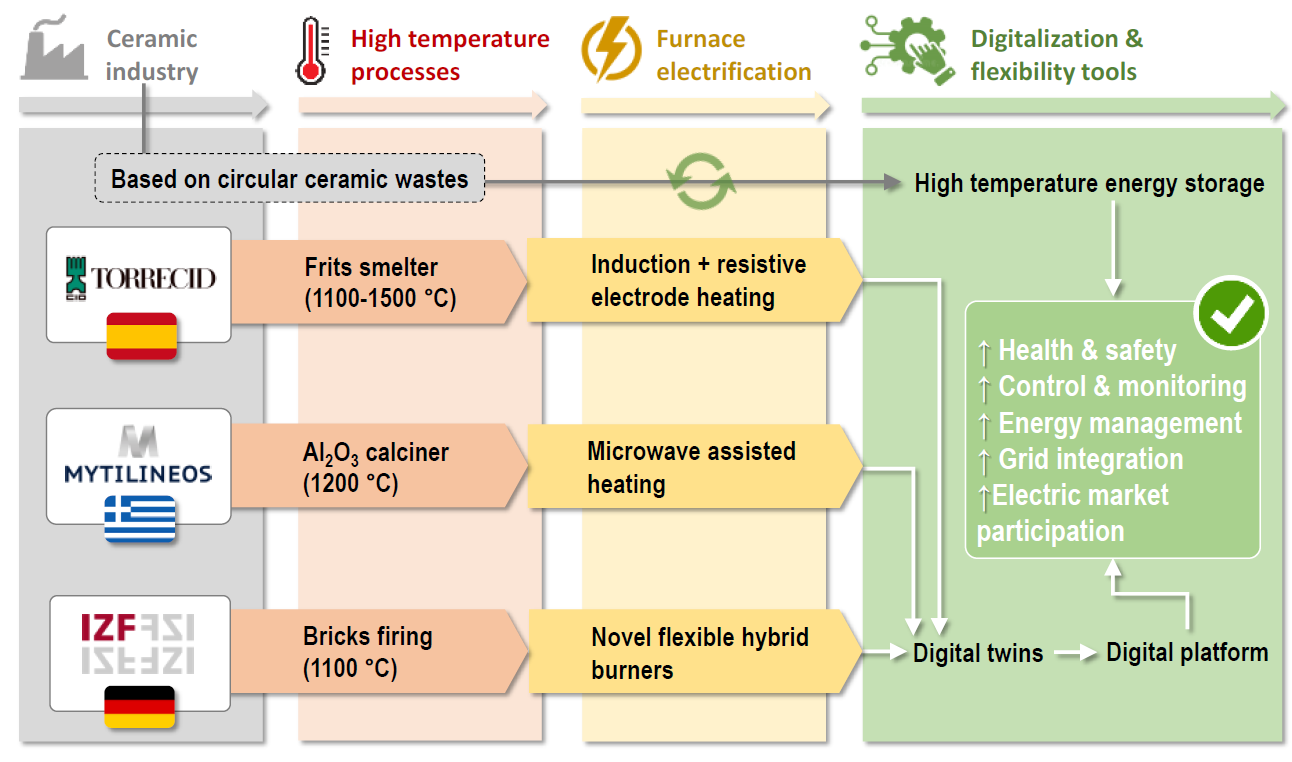

eLITHE aims to support the electrification of the ceramic industries by demonstrating sustainable and cost-effective pathways to electrify high temperature thermal processes (>1,000ºC) from the ceramic industry. Three different processes will be demonstrated at 3 different pilot sites at relevant scale:

1. A ceramic frits smelter (1,100-1,500ºC) combining induction and resistive heating through electrodes.

2. A microwave-based calcination furnace (1,200ºC) for the calcination of alumina.

3. A tunnel kiln (1,100ºC) combining radiant walls and flexible hybrid burners for bricks and tiles firing.

These technologies will be endorsed through the application of advanced modelling techniques to develop Digital Twins (DTs) of each of them, as a core tool to support design and operation. eLITHE will also involve material science to develop novel products and refractory materials compositions adapted to the new requirements of electrified processes and will test waste materials derived from the ceramic industry for high temperature energy storage applications, improving the sector circularity.

Background

Heat-related processes in Energy Intensive Industries (EIIs) are a major source of GHG emissions in the EU and account for 52% of the EIIs total emissions. Thermal processes electrification, particularly those working at high temperature, has the potential to significantly decrease GHG emissions when coupled with renewable electricity (ca. 106 MtCO2). One of the sectors that has the potential to be fully decarbonized through electrification is the ceramic sector, since almost all their emissions are heat-related, covering a wide range of processes (e.g., melting, drying, firing, sintering and calcination) that are also present in many other processing industries. However, the ceramic sector still faces many challenges for electrification, mainly: poor electric conductivity of the materials, different nature and temperatures of the processes, and the cost competitiveness compared to fossil fuels and other low-carbon technologies such as H2 combustion.

eLITHE support and promotes further development of solutions for electrification of the ceramic industries by demonstrating sustainable and cost-effective pathways to electrify high temperature thermal processes.

Aim and Objectives

The main objective of eLITHE is to design, implement and demonstrate new electrified heating systems for high temperature processes (>1,000º C) from the ceramic industries sector (melting, calcination and firing) and ensure a higher system flexibility to cope with the use of renewable energies, aiming to reduce dependence on conventional fossil fuel-based processes and achieve fully decarbonised heating processes. To achieve that the project will:

- Develop highly efficient and safe electric high temperature heating processes that replace fossil-based heating systems in the industrial ceramic sector.

- Develop and implement digital and modelling tools that facilitate the design, optimization and upscaling of electric heating technologies in industrial scenarios.

- Develop solutions to improve the electric processes flexibility and integration aiming at maximizing the use of renewable energy sources.

- Carry out a complete demonstration and validation program up to TRL 7 of advanced electric heating technologies for high temperature demand systems in 3 different industrial pilot sites.

- Establish a roadmap for the replication of eLITHE solutions in other industrial realities, considering economic viability, as well as the technical and regulatory obstacles in a large-scale deployment.

Project partners

Listed one in a row.

- CIRCE – Centro de Investigación de Recursos y Consumos Energéticos

- Universidad de Zaragoza UZ Spain University

- Instituto de Cerámica y Vidrio - Agencia Estatal Consejo Superior De Investigaciones Científicas

- Ethniko Kentro Erevnas Kai Technologikis Anaptyxis

- Institut für Ziegelforschung Essen e.V

- NEDERLANDSE ORGANISATIE VOOR TOEGEPAST NATUURWETENSCHAPPELIJK ONDERZOEK TNO

- Kungliga Tekniska Hoegskolan

- Universita’ Degli Studi di Genova

- GLASS SERVICE, a.s.

- Plustherm Point AG

- INNCEINNMAT SL

- RECOM Services GmbH

- REFRACTORY SOLUTIONS INSERTEC SL

- Torrecid SA

- MYTILINAIOS ANONIMI ETAIREIA

- ETRA Investigación y Desarrollo S.A

- SGS Portugal - Sociedade Geral de Superintendência, S.A.

- Energy Efficiency in Industrial Processes ASBL

- Fondazione Ico

Funding is provided by Horizon Europe (HADEA) - Grant Agreement No 101138325.

Timeframe: January 2024 – December 2027

Project website: HOME | eLITHE