STAMPE – Space Turbines Additive Manufacturing Performance Evaluation

Additive manufacturing (AM) as a production method for components is becoming increasingly promising around the world, this project looks at the use of AM components in the space industry, particularly in propulsion technology. With all major space agencies moving towards reusable space launchers, this process comes in handy as very complex shapes can be manufactured with relative ease and with shorter lead times, however the inherent surface roughness of the components produced using this method poses a challenge to the widespread usability of this method as designing efficient turbomachinery for the rocket launchers would require us to understand the effect of surface roughness on the performance of these turbomachines. The study of this critical phenomena is a vital step to certify this manufacturing process for the space industry which has stringent safety requirements for components.

Funded by:

Rymdstyrelsen (Swedish National Space Agency)

Time period:

2023-10-01 – 2027-10-01

Project partners:

GKN Aerospace Sweden

Background:

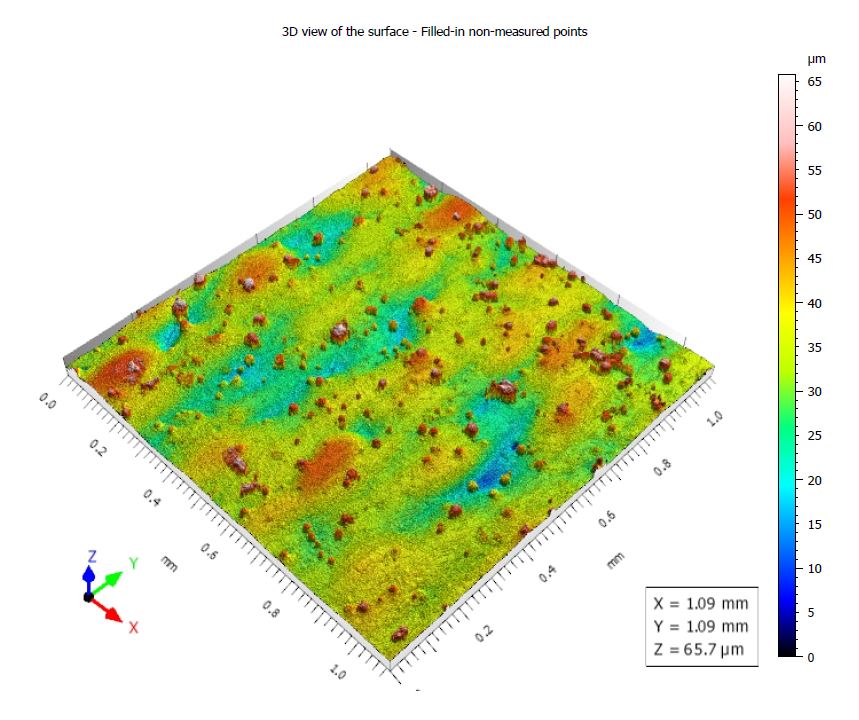

Turbomachinery are important components in a rocket engine, supplying fuel and oxygen to the thrust chamber where the combustion process takes place. The highly complex shapes and designs of the turbine vanes and blades optimized after several flow simulations can be manufactured with relative ease using AM processes, however, the roughness of the surface generated through this process could prove to counteract the benefits of the ease of manufacturing. Hence, the study of the effect of surface roughness on the flow performance (pressure losses, loss in efficiency and the study of skin friction) becomes crucial to the usage of as-built AM components in turbomachinery components.

Aims and Objectives:

The project is divided into two phases, the first phase deals with the study of the effect of surface roughness on the flow performance of AM components and the second phase deals with the study of the heat transfer properties of the components and how it is affected by the surface roughness of the components.

In order to aid in the study of these effects, simultaneous experimental and simulation campaigns would be run to gain a better understanding of the fundamental phenomena affecting flow performance. The first phase is further divided into two – the initial experiments being run in a wind tunnel to obtain better understanding of the physics behind the concept and the second set of experiments being run in a test turbine with AM blades to get an understanding of the effect at a higher TRL.

Detailed objectives:

-

To analyse the effects of surface roughness on the development of boundary layer over an additive manufactured component, skin friction development over the surface, pressure losses and to find correlations between the surface roughness and the data that is observed.

-

To capture the essence of surface roughness parameters and to implement the same in numerical simulation tools which would serve as a reference point for the experimental work mentioned above.

-

To be able to predict the nature of the flow performance data based on the experiments run for any given surface and to be able to produce and validate the results using surfaces printed in house (at KTH).

-

To perform the same evaluation of the heat transfer characteristics of AM components.