BREAD – high-temperature Heat Pump with Integrated Storage - reversed BRayton cycle for combined hEAt and colD

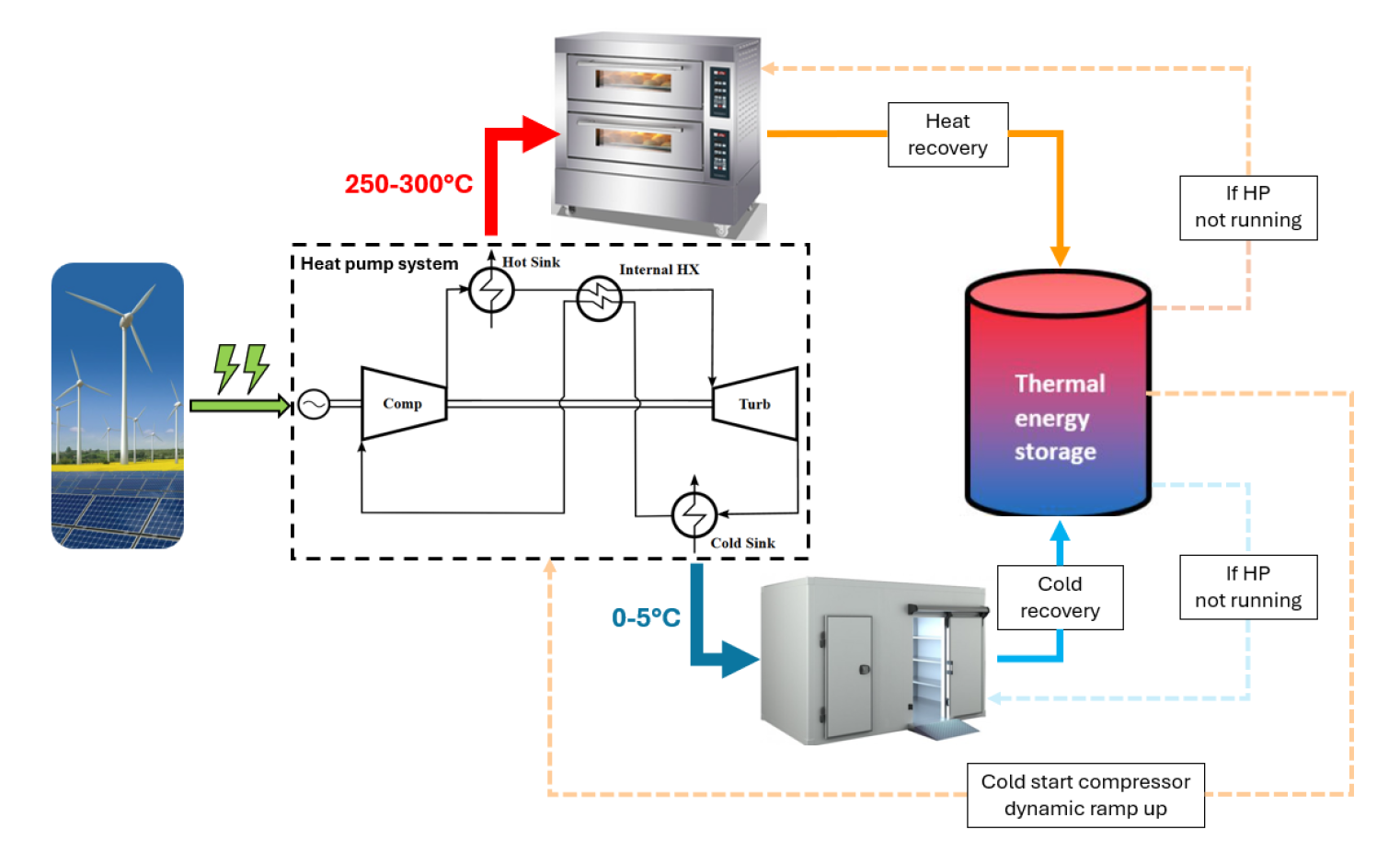

The project BREAD addresses the development of a sub-Megawatt (MW) scale heating and cooling system that will provide heat at temperatures above 250 °C (up to 400 °C) and cooling around 0 °C and below. It will smartly integrate heat pump, heat exchanger and heat storage technology. In the future, green electricity will play a significant role as a “primary” energy source for industries, and new innovations are needed to accomplish the transformation of industrial electrification.

Background

Reduction of energy use in process heat is therefore one of the key objectives in achieving carbon-neutrality by 2050. One of the main strategies for reducing heat-related emissions is transitioning heating from fossil fuel-powered to electrical heating solutions. In industrial process heat, the commercial use of high-temperature compression heat pumps depends on a low-temperature heat source at adequate temperature level and is currently limited to about 150 °C supply temperature for source temperatures around 80°C. Processes that need higher temperature heat would currently either be supplied by direct electric heating or by combustion of a renewable fuel such as green hydrogen. The BREAD system will overcome these limitations by providing a heat pump and cooling technology with a very high lift and overall, 30-50 % more efficient than direct electric heating plus cooling with a vapor compression chiller.

Aim and Objectives

The overall aim of the project BREAD is the development of a sub-Megawatt (MW) scale heating and cooling system that will provide heat at temperatures above 250 °C and cooling around 0 °C and below. It will smartly integrate heat pump, heat exchanger and heat storage technology. To achieve that the project will:

-

Design, develop, manufacture and lab test a reversed Brayton Cycle Heat Pump with a capacity of about 150 kWth, modulation range from 100-150 kWth, max. electrical input about 100 kWel, cooling capacity of about 30 kW, that delivers process heat at 250-300 °C and 0-5 °C normal cooling with a COP of 1.3-1.5.

-

Design, build and lab test a high-temperature (up to 400°C) heat storage and a low-temperature (as low as -15°C) cold storage component that allow for “cold start”, load shifting and dynamic loads in the system.

-

Design and optimize a BREAD system with respect to industrial manufacturing for specific market applications (e.g. food industry/bakery or drying processes) and analyse environmental, social and techno-economic feasibility under different scenarios.

Project Partners

Listed one in a row.

-

Fraunhofer Institute Solar Energy Systems ISE, Germany

-

Fraunhofer-Institute for Environmental, Safety and Energy Technology UMSICHT, Germany

-

MITIS SA, Belgium

-

University of Mons, Belgium

-

KTH Royal Institute of Technology, Sweden

-

MG Sustainable AB, Sweden

-

IWS-Monjé Heat Exchangers GmbH, Germany

-

MEKU Metal Processing GmbH, Germany

Funding is provided within the Clean Energy Transition Partnership 2024 programme by Energimyndigheten (for the Swedish partners) with project number P2025-02911.

Timeframe: December 2025 – November 2028

Keytags: Thermal Energy Storage, Ultra High Temperature Heat Pump, Industrial Decarbonization