VIFT — Virtual Integrated Fan and Turbine

The focus of the VIFT project is on the reduction of noise from modern efficient aero engines and the continued development of a virtual demonstrator environment aimed at turbomachinery studies. The virtual platform that will be developed further in the project has previously been shown to promote technical collaboration, research and information exchange between academia and industry in Sweden. The VIFT project will facilitate the development of methods for aircraft engine noise evaluation and innovative component designs targeting improved engine performance and increased overall efficiency.

Background

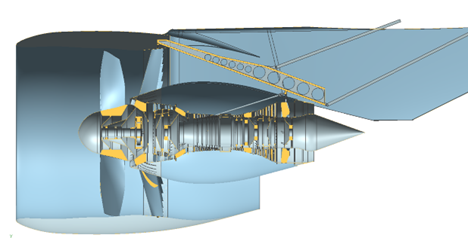

The notional aircraft engine RM400 (here also denoted as the cluster engine) is a result of earlier collaborative projects (NFFP6-VINK and NFFP7-VIND) between GKN Aerospace, Chalmers, KTH and Lund University. The collaboration between the project partners has previously been very successful and beneficial for competence building within the aerospace sector in Sweden. The platform's development has also been important for overall aircraft engine technology research in Sweden as it provides other research projects with relevant geometries and boundary conditions representative of a state-of-the-art turbofan engine.

The engine, described in [1,2], is a turbofan engine with performance goals representative of an engine with entry into service in 2035. The engine represents a virtual demonstrator environment where academia and industry can meet technically and work out new methods and test the feasibility and potential of new technologies. The focus of work packages in the project is such that participating institutions will be able to apply their deeper knowledge in special areas and investigate the applicability in the relevant environment.

With previous work in the earlier NFFP projects VINK and VIND as a starting point, detailed aerodynamic design work will be done on the fan blade and the low-pressure turbine in the cluster engine, components that are strong contributors to overall engine noise levels. Structural aspects of the fan blades will be investigated by utilizing measurement results from a past experimental test campaign of carbon fiber fan blades at KTH. Based on learnings from these validation studies, a proposal will be made for a lightweight carbon fiber fan blade design with improved aeromechanical performance. A system model for noise estimation from a turbofan engine will be developed as part of the project, which can be used in an early design phase to make balanced design choices that can enable quieter aero engines. Method development will also be done for noise estimation from a turbofan engine with and without integrated noise-reducing acoustic panels.

Aim and objectives

- Improve the aerodynamic design of the current fan blades and turbine exit guide vanes in the cluster engine.

- Detailed aerodynamic design of the low-pressure turbine stages in the cluster engine, providing input for the noise analysis.

- Detailed aeromechanical assessment of the fan blade in the cluster engine. Propose carbon fibre layup design of the fan blade for improved aeromechanical performance.

- Develop methods for evaluation of noise in a complete engine including aeroacoustics from the fan blades, fan outlet guide vanes, by-pass channel, nacelle, low-pressure turbine and turbine exit.

- Evaluation of turbofan noise, with and without liner technology implemented.

- Develop a system-level noise model. Through trajectory simulations and source models for engine and aircraft components estimate the noise signature of the system.

Project partners

GKN AEROSPACE SWEDEN AB, Sweden

Chalmers University of Technology, Sweden

Lund Institute of Technology, Sweden

KTH Royal Institute of Technology, Sweden

Funding is provided by Vinnova (NFFP8 program)

Timeframe: 1 Aug 2023 – 31 Aug 2024

Researchers

Publications

Publications coming out of this project will be available through Diva

References

[1] Grönstedt, T., Xisto, C., Zhao, X., Jonsson, I., Reinap, A., Genrup, M., Glodic, N., Guiterrez Salas, M., Lejon, M., Avellán, R. and Mårtensson, H. 2022, ”Multidisciplinary Assessment of a Year 2035 Turbofan Propulsion System”, ICAS-2022-0832, 33rd Congress of the International Council of the Aeronautical Sciences.

[2] Lejon, M., Grönstedt, T., Glodic, N., Petrie-Repar, P., Genrup, M., and Mann, A., 2017, "Multidisciplinary design of a three-stage high-speed booster," GT2017-64466, Proc. ASME Turbo Expo 2017: Turbine Technical Conference and Exposition, ASME.