GeoSUSTAIN – Sustainable Medium-Depth Geothermal Solutions with Solid Media Thermal Energy Storage for H/C

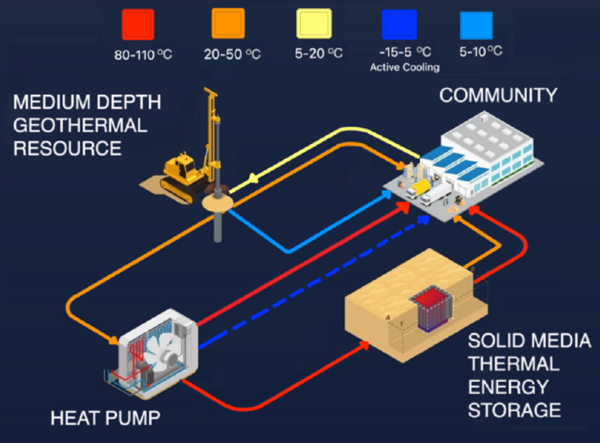

The GeoSUSTAIN project aims to develop an efficient, zero-emission geothermal-based solution for industrial heating and cooling. This project will focus on integrating medium-depth geothermal system with underground solid media thermal energy storage to provide scalable, flexible, and cost-effective technological solutions for heating and cooling purposes.

Background

According to EUROSTAT, 25.1% of the EU’s final energy demand in 2022 was attributed to the industrial sector. Achieving significant energy savings and accelerating the penetration of renewable energy sources (RES) in this sector is, therefore, both crucial and urgent. Process heating accounts for the largest share of this energy consumption, representing 66% of the total demand. A closer examination of temperature levels reveals that 37% of the heat demand corresponds to process temperatures below 200°C, a range where substantial efficiency improvements are possible. In fact, a systematic analysis of heat flow through industrial processes conducted by JRC2, has demonstrated that only a fraction of industrial processes requires high temperatures and approximately one-fourth of the heat demand in industry is associated with low temperature processes, which can be offered by geothermal energy as a straightforward and cost-effective solution. For processes necessitating higher temperatures, Heat Pumps (HPs) integrated with thermal energy storage (TES) systems can serve as a good solution, to meet the temperature requirements. Thus, the integration of geothermal energy with HPs and suitable thermal energy storage technologies poses substantial potential for enhancing energy efficiency in the industrial sector, which currently holds a minor share of the geothermal energy portfolio.

Aim and Objectives

The GeoSUSTAIN project aims to:

-

Design and test medium-depth geothermal heat exchangers for an efficient heat extraction and storage. This can enable broader adoption in various industrial settings across Europe by 2030.

-

Develop an innovative underground solid media thermal energy storage as a cost-effective and space-efficient solution. This system will offer thermal flexibility and reliability, supporting the goal of enabling 100% climate-neutral heating and cooling by 2050.

-

Establish an advanced AI-based system to optimize energy extraction, storage, and distribution in real-time. Intelligent control of the integrated GeoSUSTAIN ensures that the system adapts to variable industrial demands, supporting TRI4’s focus on increasing the operational flexibility of heating and cooling.

-

Conduct both lab-scale and pilot-scale demonstrations to validate the effectiveness, cost savings, and scalability of the integrated GeoSUSTAIN system. These demonstrations will support wider adoption and contribute to the CETPartnership goal of transitioning towards zero-emission heating and cooling.

Project Partners

-

UiS (University of Stavanger, Norway) – coordinator

-

KTH (Royal Institute of Technology, Sweden)

-

AIT (Austrian Institute of Technology, Austria)

-

TNO (Netherlands Organization for Applied Scientific Research, Netherlands)

-

UoC (University of Calgary, Canada)

-

WE (Warsaw Enterprise Institute, Poland)

-

BD (Bengt Dahlgren, Sweden)

-

Lyse (Norway)

-

Helin (Netherlands)

-

ET (EnerTrans, Netherlands)

-

NC (NorConsult, Norway)

-

WI (Well Intercept, Norway)

-

TSS (ThermaStor Solutions, Canada)

-

IS (Integrated Sustainability, Canada)

-

PNTEC (Euro-Centrum Science and Technology Park, Poland)

-

RK (Reve Kompost, Norway)

-

Pharmaceutical Takeda Manufacturing (PTM, Austria)

-

SB (Statsbygg, Norway)

Funding is provided by Clean Energy Technology Partnership

Timeframe: 2025 - 2028

Keytags: Geoenergy, Heat pumps, Industrial Heat, Underground Thermal Energy Storage

Researchers

For further information about this project, please contact Andrew Martin