Experimental and numerical study on surface roughness on external surfaces by AM printed blades

Thesis Description

The advancements of additive manufacturing (AM) in metal alloys have been great during the last years. The benefits in terms of a minimum of material usage addressing material circularity, overall production cost savings and the increased degrees of freedom in possible new optimized designs, which in traditional production machining may be limited. To keep the cost benefits of using AM the manufacturers in the aerospace business are looking into using “raw” printed products instead of having costly after treatments in terms of surface polishing. There will be a penalty, in terms of increased friction losses due to increased surface roughness, and of importance for the designers is to be able to predict that penalty. If the overall circularity significantly improves then a certain performance drop may be acceptable. The surface of an AM part is typically very stochastic with half-melted particles, and many times in an irregular pattern. Modelling of surface roughness often results in a large uncertainty. Commonly used design correlations from literature are not valid anymore. At HPT there is an ongoing research project investigating the roughness of the surface and its aerodynamic implications, quantification of it through surface metrology and aerodynamic performance measurements in a wind tunnel experiment with a generic blade. To couple it with the design process at industry, numerical CFD simulations are conducted. Typically, the numerical simulations in an industry design process are of lower fidelity, RANS/URANS, where the surface roughness is mimicked with altering the wall-shear stress based on the concept of equivalent sand grain roughness that is not reflecting the true AM surface. An overall objective in the project is to look into this modelling. The MSc thesis work will focus on performing wind tunnel experiments of a newly developed test setup, evaluate those and with parallel CFD modelling of the test setup.

A literature study is followed by a numerical study to get familiarized with the area. A set of parametric wind tunnel tests will be performed to provide validation data for necessary adjustments of the numerical model.

The thesis is conducted within an applied commissioned research project. Collaboration with industry is inherent, allowing participation in project meetings during the study. The student shall write a technical report (in English) and present/defend the findings at a public seminar at KTH.

Prerequisites

To be applicable, the student should have adequate knowledge of fluid mechanics (KTH course SG1220 or corresponding). Turbomachinery courses like MJ2523 have strong merits as well as heat transfer courses.

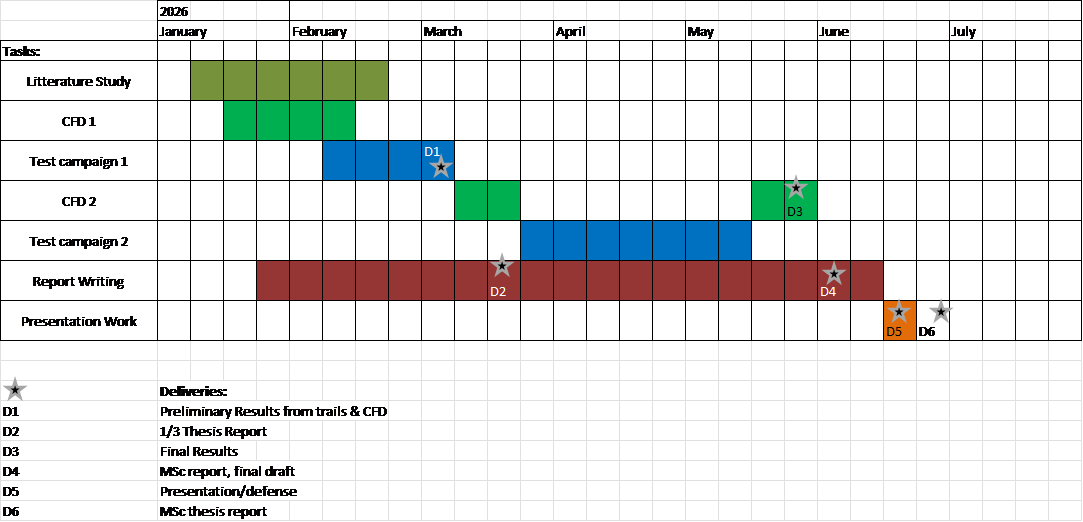

Time Plan

January 2026 – June 2026 (can be discussed)

Proposed Time Schedule