Influence of Surface Roughness on Methane Pyrolysis Stability in Rocket Cooling Channels

Within the MERIT project we study the characteristics of methane under conditions found in rocket nozzle cooling channels, i.e. elevated inflow temperature and a high single-sided heat load.

Background

The MERiT project—a collaboration between KTH Royal Institute of Technology, GKN Aerospace, and the European Space Agency (ESA)—investigates methane as a regenerative coolant for reusable rocket engines. Under high heat loads, methane can undergo thermo-catalytic decomposition (pyrolysis), forming solid carbon that reduces heat transfer and shortens engine life. Recent studies have explored how fuel composition and material properties affect this process. New findings show that surface roughness, particularly from additive manufacturing, can significantly intensify catalytic activity and carbon deposition. A clearer understanding of this relationship is essential for predicting engine fouling and optimizing cooling-channel design.

Thesis aim

The thesis project aims to quantify the effect of surface roughness on the pyrolysis stability of methane under rocket-relevant conditions.

Specific objectives include:

-

Prepare and characterise the surface topography of nickel- and Inconel-based alloys using profilometry.

-

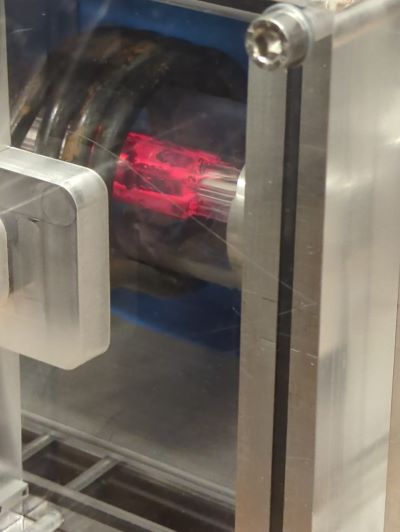

Perform controlled pyrolysis experiments at 700–850 °C in the MERiT Small Pyrolysis Setup (SPS).

-

Measure hydrogen production and carbon deposition using gas chromatography and real-time thermal-conductivity sensors.

-

Develop correlations between surface metrics and pyrolysis rate, onset temperature, and deposit morphology.

-

Compare results with previous MERiT data.

Deliverables

The main deliverables of the project include but are not limited to:

-

Final thesis report and presentation of the project

-

Design and technical specification of the improved small pyrolysis setup

-

Material measurement results

Duration

The project should start in Jan-Feb 2026 at the latest, with a duration of up to 6 months.